I was recently at a high-level tech summit where the room was filled with software engineers and data scientists, all of whom were visibly anxious about the latest generative AI updates. In the middle of the panic, a partner at a major venture capital firm stood up and said something that changed the temperature of the room.

He noted that if you want your child to have a job that is 100 percent safe from AI for the next thirty years, do not send them to coding school. Send them to become a master electrician or a specialized site foreman.

If you are wondering whether AI will replace construction workers, the answer is a resounding no. In fact, construction is one of the safest professions in the entire global economy.

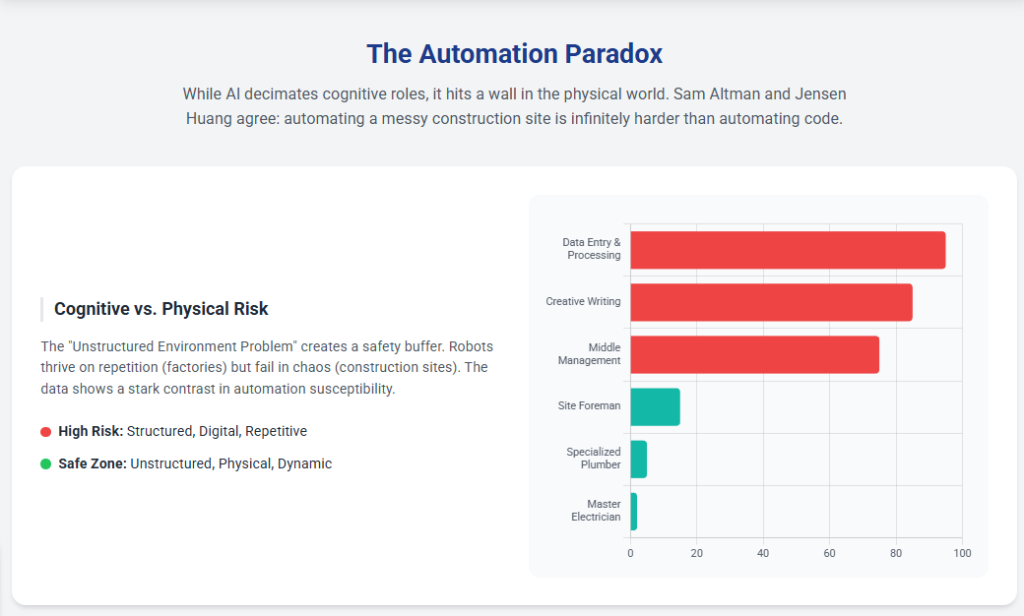

While AI is currently gutting middle management and creative writing roles, it is hitting a massive physical wall when it comes to the job site.

As OpenAI CEO Sam Altman recently noted, we are seeing that it is much easier to automate a cognitive task than it is to automate a physical one in an unstructured environment.

Nvidia CEO Jensen Huang has echoed this, stating that the next decade will actually see a blue-collar boom because the physical infrastructure required to power the AI revolution—the data centers and chip factories—can only be built by human hands.

The Blue-Collar Fortress: Why Construction is Safe

In 2026, we have the technology to write a legal brief in seconds, but we still do not have a robot that can navigate a muddy, ever-changing construction site to install a complex HVAC system. The safety of this profession comes down to the sheer unpredictability of the physical world.

The Unstructured Environment Problem

AI thrives in structured environments like a chess board or a factory floor where everything is in a fixed position. A construction site is the opposite. It is a chaotic mix of weather changes, shifting soil, moving equipment, and human coworkers. A robot that works perfectly on a level concrete slab will fail the moment it hits a patch of uneven gravel or a gust of wind.

The Problem of Project Uniqueness

Unlike manufacturing, where you build a million identical widgets, every building is a unique prototype. Even if you use the same blueprints, the local building codes, the specific terrain, and the way the materials settle are always different. AI struggles with one-off problem solving, which is the baseline requirement for every construction worker every single day.

The Threat from China: A Different Kind of Pressure

While construction workers in the West are safe from being replaced by a local robot, there is a legitimate competitive threat coming from the East. China is currently leading the world in modular construction and automated prefabrication.

The Modular Revolution

China has perfected the art of building skyscrapers in weeks by using massive, highly automated factories to create 3D building modules. These are then shipped to a site and stacked like Lego bricks. The threat is not that a robot will show up on your local site and take your hammer; it is that the building itself might be manufactured overseas and shipped to your city as a finished product.

The Digital Twin Supremacy

Chinese construction firms are heavily investing in digital twins—exact virtual replicas of a project that use AI to predict every single bolt and wire needed before the ground is even broken. This level of extreme efficiency allows them to underbid Western firms on massive international infrastructure projects. For the individual worker, the threat is not automation, but rather a global shift in how buildings are designed and delivered.

Five Reasons Why Humans Remain Irreplaceable

If you are in the trades, here is why your job security is currently higher than a Silicon Valley developer.

- Multimodal Sensory Input: A human worker uses sight, sound, touch, and even smell to diagnose a problem. An experienced plumber can hear a pipe vibration or feel a subtle temperature shift that a sensor might miss.

- Real-Time Troubleshooting: When a delivery is late or a material is defective, a human foreman makes ten different adjustments on the fly to keep the project moving. AI agents currently lack the high-level executive function to manage multi-party logistical failures.

- The Accountability Gap: If a bridge collapses, society demands a human engineer and a human contractor to take responsibility. You cannot put a software license on trial, and insurers are currently refusing to cover projects that do not have significant human oversight.

- Fine Motor Skills and Dexterity: While we have robots that can lay bricks in a straight line, we are decades away from a robot that can delicately thread a wire through a crowded ceiling plenum or fit a custom piece of trim on a historic restoration.

- Physical Power with Intelligence: Human workers are the ultimate hybrid. They have the strength to move materials and the intelligence to know exactly where they go. Building a robot with both the power of a crane and the precision of a surgeon is prohibitively expensive.

Frequently Asked Questions

Is the construction industry becoming more high-tech?

Yes, but in a way that helps workers rather than replacing them. In 2026, we are seeing a surge in exoskeletons that reduce the physical strain on a worker’s back and AR glasses that overlay blueprints onto the real world. The tech is making the job easier and extending the careers of aging professionals.

Should I be worried about 3D printed houses?

3D printing is great for the shell of a house, but it still represents a tiny fraction of the market. Even with a printed wall, you still need humans for the foundation, the roofing, the electrical, the plumbing, and the finishing. It is just another tool in the belt, not a replacement for the crew.

What construction roles are most at risk?

The roles at risk are primarily in the back office. Estimators, schedulers, and lower-level project coordinators are seeing their tasks heavily automated by AI. If your job involves a keyboard more than a tool belt, you are in the path of the storm.

Why are salaries for trades increasing if AI is so powerful?

It is a simple case of supply and demand. As AI makes white-collar work more precarious, fewer people are entering the trades. This has created a massive labor shortage. In 2026, a master welder can easily out-earn a mid-level software manager because the welder’s skill cannot be replicated by a server farm.

Final Thoughts: The Return to the Real World

We are witnessing a great rebalancing of the economy. For thirty years, we were told that the future belonged to the people who moved bits of data. In 2026, we are realizing that the future belongs to the people who can move atoms.

AI is a brilliant researcher and a fast writer, but it is a terrible carpenter. If you work in construction, you are the final guardrail of the physical world. Your job is not just safe; it is becoming the foundation of a new, high-value economy where hands-on mastery is the ultimate premium asset.